AI-Powered Business Transformation

AI for your future. Automate, gain insights, transform.

A large food distributor struggled with maintaining freshness and safety of perishable goods. Traditional methods were inefficient and led to waste. They needed a system for real-time data to ensure product quality and safety.

A large food distribution company faced significant challenges in maintaining the freshness and safety of their perishable goods, including fruits, vegetables, and poultry. Traditional methods of monitoring freshness and detecting diseases were labor-intensive, prone to errors, and often resulted in significant waste. The company needed a more reliable and efficient solution to ensure the quality of their products from farm to table.

According to a senior member of the leadership team, ‘Our traditional approaches were falling short in maintaining optimal product freshness and safety. We required a cutting-edge system capable of delivering real-time data to minimize waste and uphold stringent food safety regulations.

To address these challenges, the food distribution company partnered with Lektik to develop an AI-based solution. The primary objectives were:

– Ensure Freshness: Accurately capture and monitor the freshness of perishable goods.

– Detect Diseases: Identify diseases in fruits, vegetables, and poultry early to prevent the spread.

– Reduce Waste: Minimize food waste by optimizing the handling and distribution process.

Lektik’s approach involved designing and implementing an advanced AI-based solution tailored to the company’s needs:

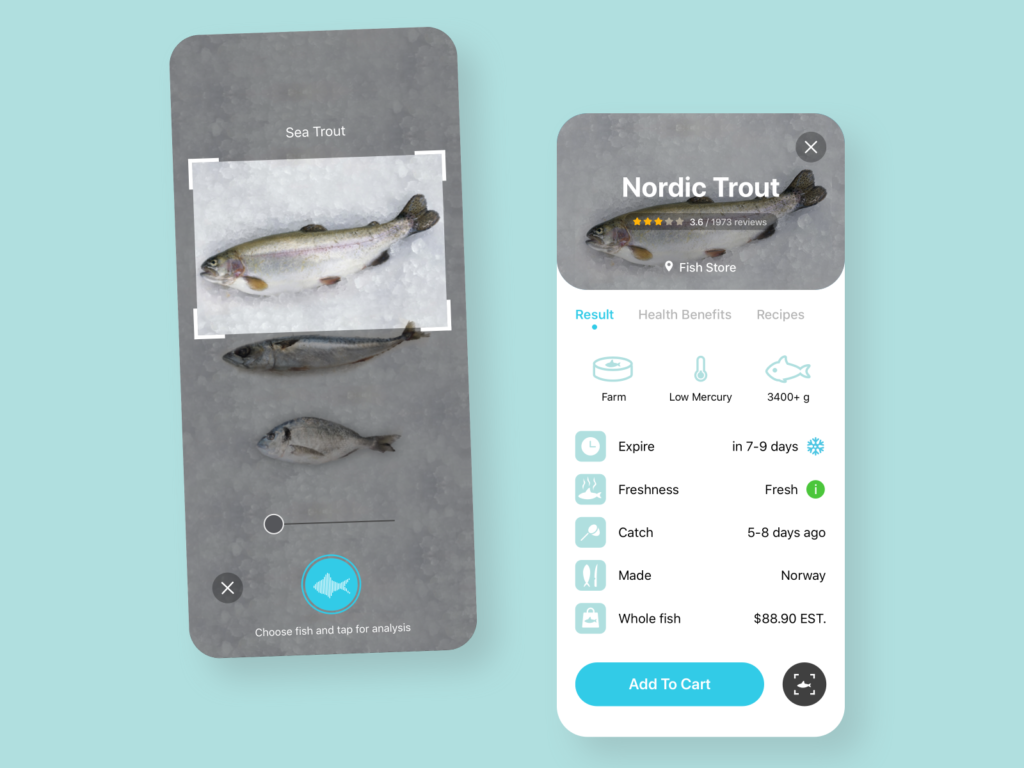

1. AI-Powered Freshness Monitoring

– The system utilized advanced AI algorithms to analyze visual and sensory data from fruits, vegetables, and poultry. By capturing high-resolution images and using sensors to detect gas emissions and temperature changes, the AI could accurately assess the freshness of products in real time.

2. Disease Detection and Prevention

– Machine learning models were trained to recognize patterns and anomalies indicative of diseases in perishable goods. By analyzing images and sensor data, the AI system could detect signs of spoilage or contamination early, allowing for timely intervention and prevention of disease spread.

3. Real-Time Data Integration and Analysis

– The solution integrated data from various sources, including IoT devices, cameras, and sensors placed throughout the supply chain. This real-time data was analyzed to provide actionable insights and recommendations for handling, storage, and distribution.

4. Automated Alerts and Reporting

– The system included automated alerts and comprehensive reporting features. When the AI detected potential issues with freshness or signs of disease, it would immediately notify the relevant staff, enabling quick action to address the problem. Detailed reports provided insights into trends and helped optimize operations.

5. Predictive Analytics for Inventory Management

– The AI solution also employed predictive analytics to forecast the shelf life of products based on historical data and real-time conditions. This helped in planning and optimizing inventory, reducing waste, and ensuring that only the freshest products reached customers.

1. Integration with Existing Systems

– Integrating the AI solution with the company’s existing systems was a complex task. Lektik’s team conducted a thorough analysis and developed a detailed integration plan to ensure seamless operation and compatibility.

2. Training and Adoption

– Extensive training was required for the company’s staff. Lektik provided in-depth training sessions and resources, including practical workshops and ongoing support, to ensure effective use of the new technology.

3. Customization for Diverse Products

– The solution needed to be customized to handle a wide range of perishable goods. Lektik worked closely with the client to tailor the AI models and system features to meet the specific needs of different product types.

1. Improved Freshness Monitoring

– The AI-powered system provided accurate and real-time assessments of product freshness, significantly improving the company’s ability to ensure quality and reduce waste.

2. Early Disease Detection

– Early identification of diseases in fruits, vegetables, and poultry allowed for timely interventions, reducing spoilage and contamination risks.

3. Reduced Waste

– Optimized handling and distribution processes, guided by AI insights, led to a significant reduction in food waste and improved inventory management.

4. Enhanced Food Safety

– The robust disease detection and monitoring capabilities of the AI system ensured higher standards of food safety, building trust with customers and stakeholders.

The deployment of Lektik’s AI-based solution has revolutionized the company’s approach to managing the freshness and safety of perishable goods. By leveraging advanced AI technology, the company can now ensure the highest standards of quality, reduce waste, and maintain the safety of their products from farm to table. This case study demonstrates how AI can transform food distribution operations, offering a model for other companies facing similar challenges.

A senior executive expressed confidence in the solution’s impact, stating, ‘This groundbreaking innovation positions us at the forefront of the food distribution industry and sets a new benchmark for quality and efficiency.’

– Food Distribution Companies: Large-scale distributors can leverage AI technology to monitor the freshness and safety of perishable goods, reducing waste and ensuring quality.

– Retail Supermarkets: Supermarkets can adopt AI solutions to enhance inventory management and provide fresher products to customers.

– Agricultural Producers: Farmers and producers can use AI to monitor crops and livestock for signs of disease, optimizing yield and product quality.

– Food Processing Plants: Processing facilities can implement AI-based monitoring systems to ensure the safety and quality of processed foods.

“The AI solution provided by Lektik has been a catalyst for growth. The system’s accuracy and user-friendliness have exceeded our expectations. We’re confident in our ability to maintain the highest quality standards and deliver exceptional value to our customers.”

Need a tailored solution? Let us build it for you.

Connect Today